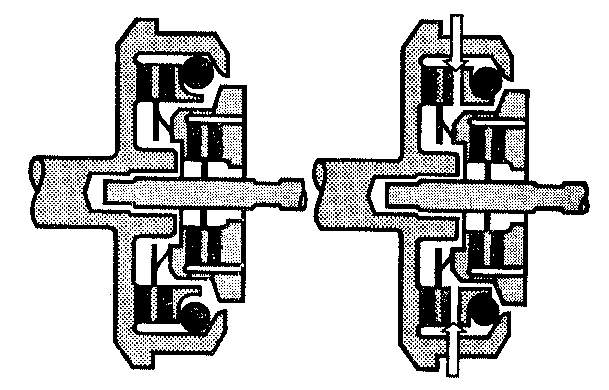

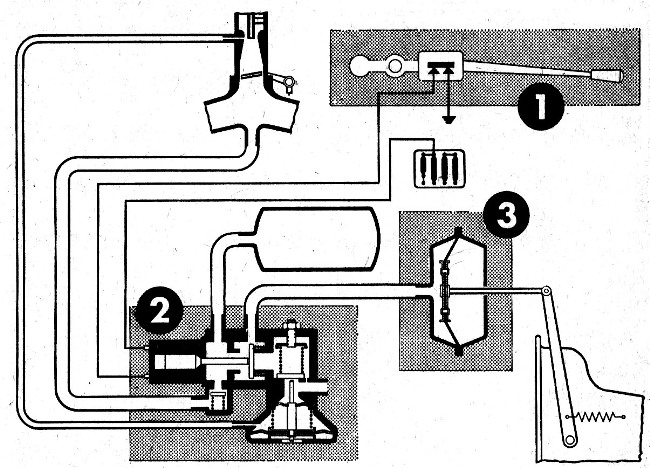

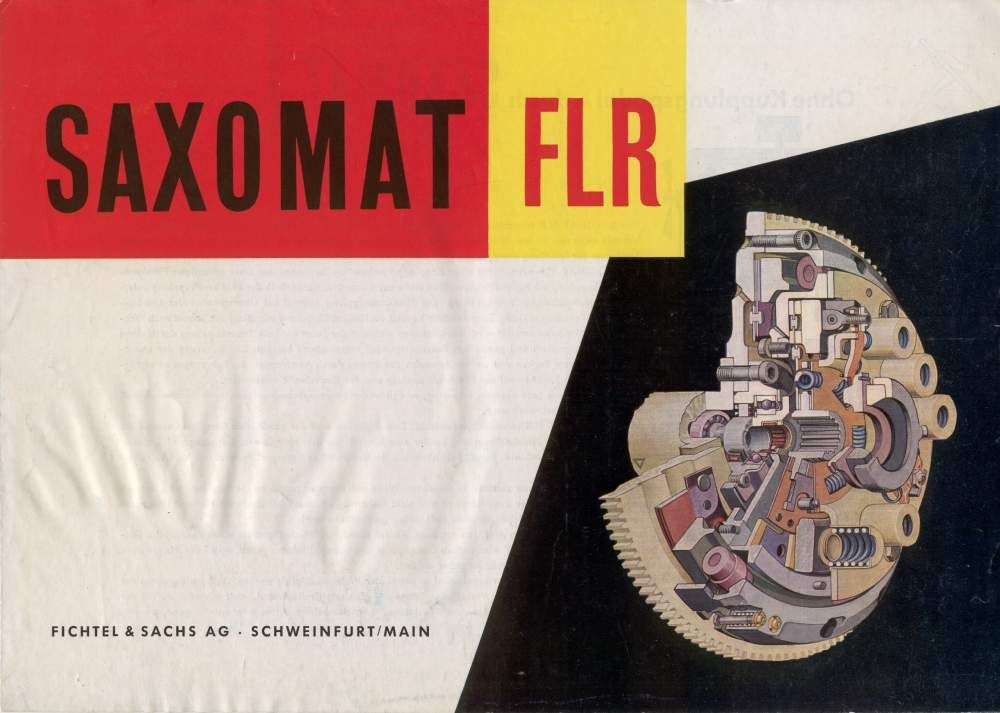

The Olymat (Saxomat) clutch is a combination of two single dry plate clutches: one is operated by centrifugal force and utilises a bronze friction material and another is a normal type with asbestos material and is operated by a release bearing, a clutch lever and a vacuum actuator. The illustration to the left shows the high-rpm situation vhere the centrifugal clutch is engaged. The illustration to the right shows the low-rpm situation where the centrifugal clutch is released.The purpose of the clutch control system is to release the clutch whenever the gearlever (1) is operated and reengage the clutch, when a new gear has been selected, and the accelerator pedal is depressed. Vacuum is supplied from the intake manifold and stored in a reservoir. When the gearlever is touched electric current is supplied to the solenoid in the controlvalve (2). Vacuum is transferred to the vacuum diaphragm actuator (3) which pulls the clutch lever and releases the clutch. The diaphragm-valve-system at the right end of the control valve (2) ensures a controlled vacuum release and thereby a soft reengagement of the clutch. The thin hose connection to the upper part of the carburettor signals a hard depressed accelerator which hastens the clutch take-up.The Fichtel & Sachs Saxomat clutch control valve mounted in Opel Rekord P2 1961The pull rod from the vacuum actuator is seen under the clutch control valveVacuum actuator from scrapped car. The pull rod normally attached to the hexagon in the center is broken off.Pressure plate and friction disk belonging to the centrifugal clutch. Note the 6 centrifugal weights.The bronze padding on the friction disk is completely worn down.Pressure plate and friction disk seen from other side. Both are worn down.

The Saxomat was an evolution of the F & S-roller centrifugal clutch as a lower-cost alternative to models with automatic transmission. Pricing of the Saxomat was therefore between automatic transmissions of the day, and a conventional “manual” change.

On Auto Union/DKW cars the Saxomat was only originally available on Coupe and four door versions of the 3=6 series (the F93 3=6 Coupe and the F94). By 1960, this was extended to the two door “standard saloon” version of the Auto Union 1000 (it was available on the 1000S Coupe and Four door also).

Also, in post-war Germany, there was a market for vehicles that could be adapted for use by persons that had lost one or both legs during the war. As automatic transmissions were a rarity there, at that time, the automatic clutch option fulfilled that requirement nicely.

Cars with a Saxomat clutch do not have a clutch pedal. The Saxomat consists of two independent systems, the centrifugal clutch, and the servo clutch. The centrifugal clutch is engaged above certain engine rpms by centrifugal force (RPM as adjusted), acting on spinning weights inside the clutch, similar to a centrifugal governor.

As stated above, essentially, the Saxomat works with two parallel clutches and a freewheel:

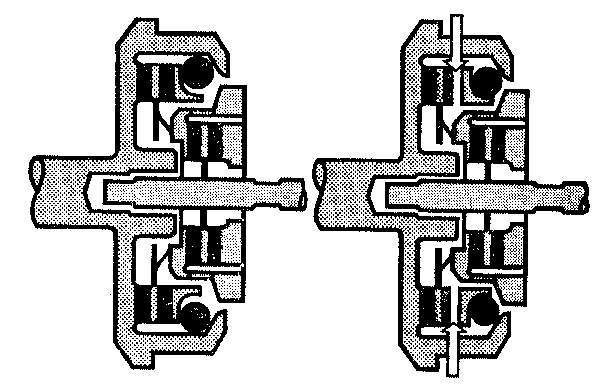

The Saxomat clutch is a combination of two single dry plate clutches: one is operated by centrifugal force and utilises a bronze friction material and another is a normal type with asbestos material and is operated by a release bearing, a clutch lever and a vacuum actuator. The illustration to the left shows a high-rpm situation where the centrifugal clutch is engaged. The illustration to the right shows a low-rpm situation where the centrifugal clutch is released.

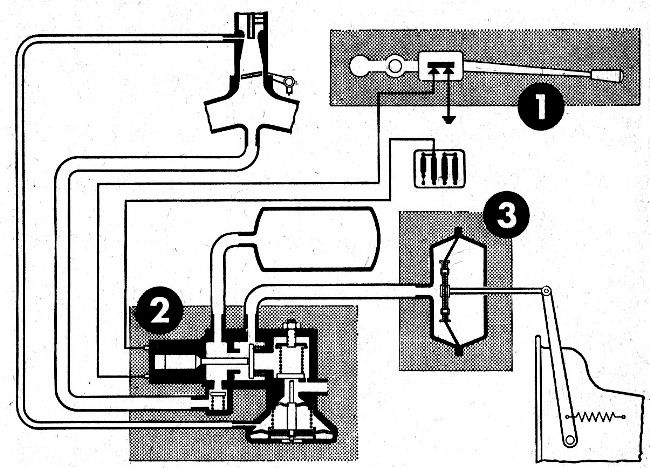

The purpose of the clutch control system is to release the clutch whenever the gear lever (1) is operated and re-engage the clutch, when a new gear has been selected, and the accelerator pedal is depressed. Vacuum is supplied from the intake manifold and stored in a reservoir. When the gear lever is touched electric current is supplied to the solenoid in the control valve (2). Vacuum is transferred to the vacuum diaphragm actuator (3) which pulls the clutch lever and releases the clutch. The diaphragm-valve-system at the right end of the control valve (2) ensures a controlled vacuum release and thereby a “soft” re-engagement of the clutch. The thin hose connection to the carburettor signals a hard depressed accelerator which hastens the clutch take-up.

The servo clutch used an electric switch that supplied manifold vacuum via an actuator valve to a reservoir that disengaged the clutch. The clutch is disengaged automatically whenever the gear shift lever was touched.

Here, above, the gear lever switch is visible in this shot of a DKW “Fissore” Saxomat, just above the rubber boot on the gear lever.

تداول رواد مواقع التواصل الإجتماعي، مقطع فيديو لمهندس مصري إبتكر طريقة جديدة لتحويل سيارة مصممة لتعمل بنظام ناقل الحركة اليدوي إلى سيارة تشبه طريقة قيادة السيارات الأوتوماتيكي.

ويظهر في الفيديو المتداول، مهندس يقوم باختبار قيادة سيارة "بيجو 305" مانيوال وتحريك عصا الفتيس اليدوي بدون دواسة فصل تروس ناقل الحركة، ولم يكشف عن تفاصيل تحويل السيارة التي تعمل بناقل حركة يدوي إلى سيارة تسير بناقل حركة ليس أوتوماتيكي.

https://www.youtube.com/watch?v=rlDJ0xlY564

النتائج 11 إلى 20 من 41

مشاهدة المواضيع

-

رقم العضوية : 24371

تاريخ التسجيل : 07Nov2008

المشاركات : 6,251

النوع : ذكر

الاقامة : القاهرة

السيارة: لايوجد

السيارة[2]: لايوجد

دراجة بخارية: لا يوجد

الحالة :

بيجو 305 بدون دبرياج الشكل القديم مصرى 100%!2017! -

بيجو 305 بدون دبرياج الشكل القديم مصرى 100%!2017! -

انشر الموضوع فى :

انشر الموضوع فى :

المواضيع المتشابهه

-

حد جرب النترا اي دى 2017 ؟ Elantra ad 2017 الشكل الجديد

بواسطة ahmedmohsen8 في المنتدى هيــونــداىمشاركات: 7آخر مشاركة: 17-09-2016, 04:40 AM -

بيجو 301 ام صنى الشكل القديم

بواسطة Ahmed_abas في المنتدى قســـــــــم المقارنــــاتمشاركات: 6آخر مشاركة: 03-01-2015, 11:08 PM -

بيجو 301 vs سيراتو 2013 (الشكل القديم)

بواسطة yomnaa في المنتدى قســـــــــم المقارنــــاتمشاركات: 9آخر مشاركة: 20-03-2014, 06:38 PM -

سعر نيسان صني الشكل القديم (abs/بدون)

بواسطة alaaosmanakl في المنتدى نيـــــــــسانمشاركات: 11آخر مشاركة: 05-08-2012, 02:31 PM -

استفسار عن رعشه في دبرياج النترا 2011 الشكل القديم

بواسطة memotitoz في المنتدى هيــونــداىمشاركات: 2آخر مشاركة: 27-01-2012, 04:26 PM

الكلمات الدلالية لهذا الموضوع

Content Relevant URLs by vBSEO 3.6.0 PL2

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

![Shine[1]](images/smilies/shine[1].gif)

![Y Hi 3[1]](images/smilies/Y_hi_3[1].gif)

رد مع اقتباس

رد مع اقتباس

المفضلات